GR Cup Reliability Modifications

As track enthusiasts, we can learn a lot by studying how the pros at Toyota Racing Development (TRD) and Toyota Gazoo Racing North America (TGRNA) set up the GR Cup car.

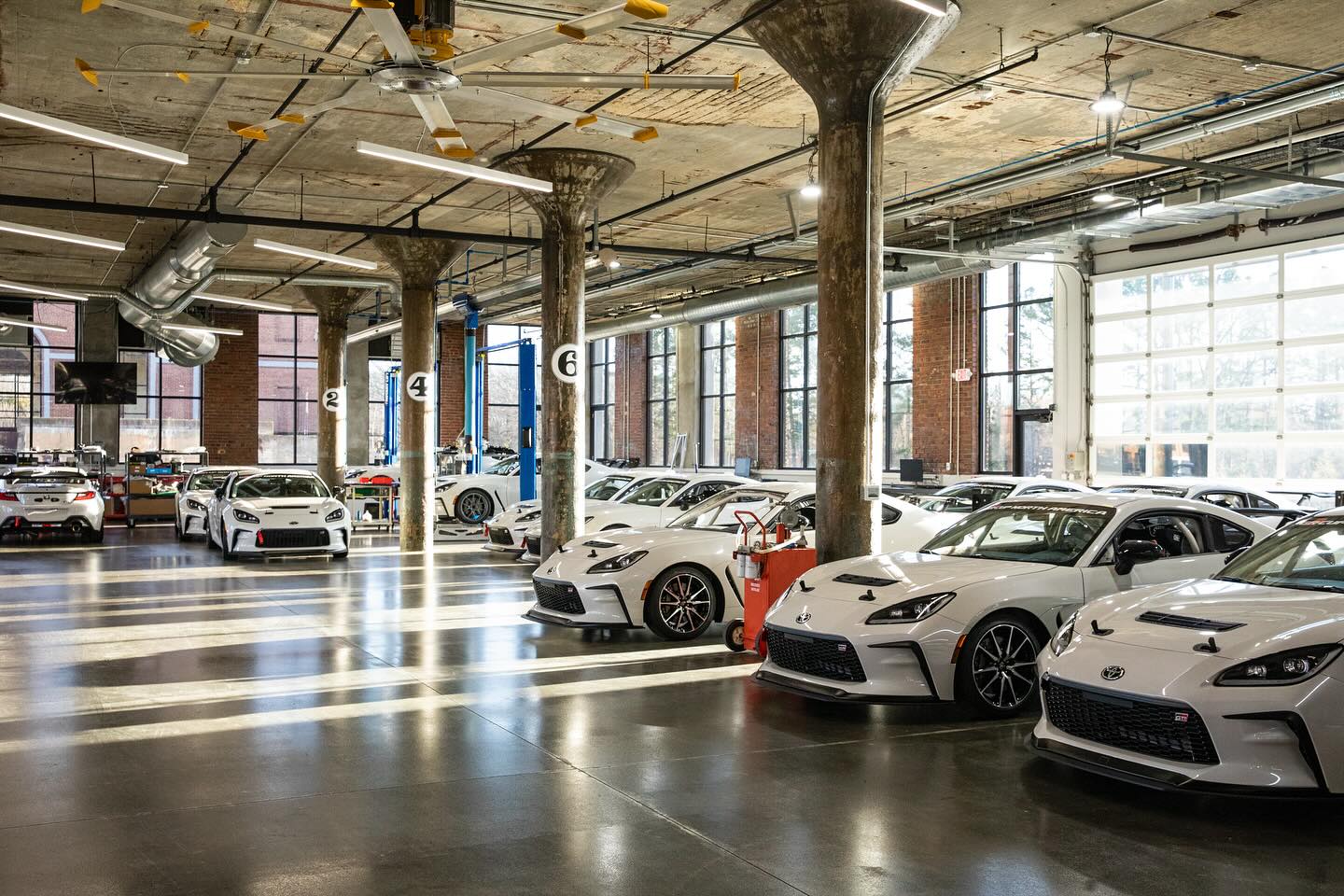

The GR Cup spec series debuted in 2023 and was renewed for the 2024 season, currently underway. All GR Cup cars arrive at TGRNA's North Carolina garage as Base model GR86s, straight off the same production line as street-bound cars. They are then modified to handle the demands of spec racing.

The series runs 7 race weekends per year, each with the following schedule:

| Event | Duration (min) |

|---|---|

| Practice 1 | 30 |

| Practice 2 | 30 |

| Qualifying 1 | 15 |

| Race 1 | 45 |

| Qualifying 2 | 15 |

| Race 2 | 45 |

That's about 21 hours per car of official on-track action per year. If you compare that to a typical HPDE (with 5-6 20-minute sessions per day), the GR Cup schedule is around the same runtime as 12 HDPEs. However, we would expect GR Cup cars to be pushed harder than track day cars and the longer duration race sessions also require a more robust cooling setup.

Through discussion with people directly involved with GR Cup and attending 2 race weekends at my local track, Sonoma Raceway, I've compiled detailed information about how these cars were modified by Toyota to be race-ready.

I'll focus here primarily on engine reliability modifications, but I may make another post in the future on performance mods.

All photos are my own unless otherwise noted.

Oil cooler

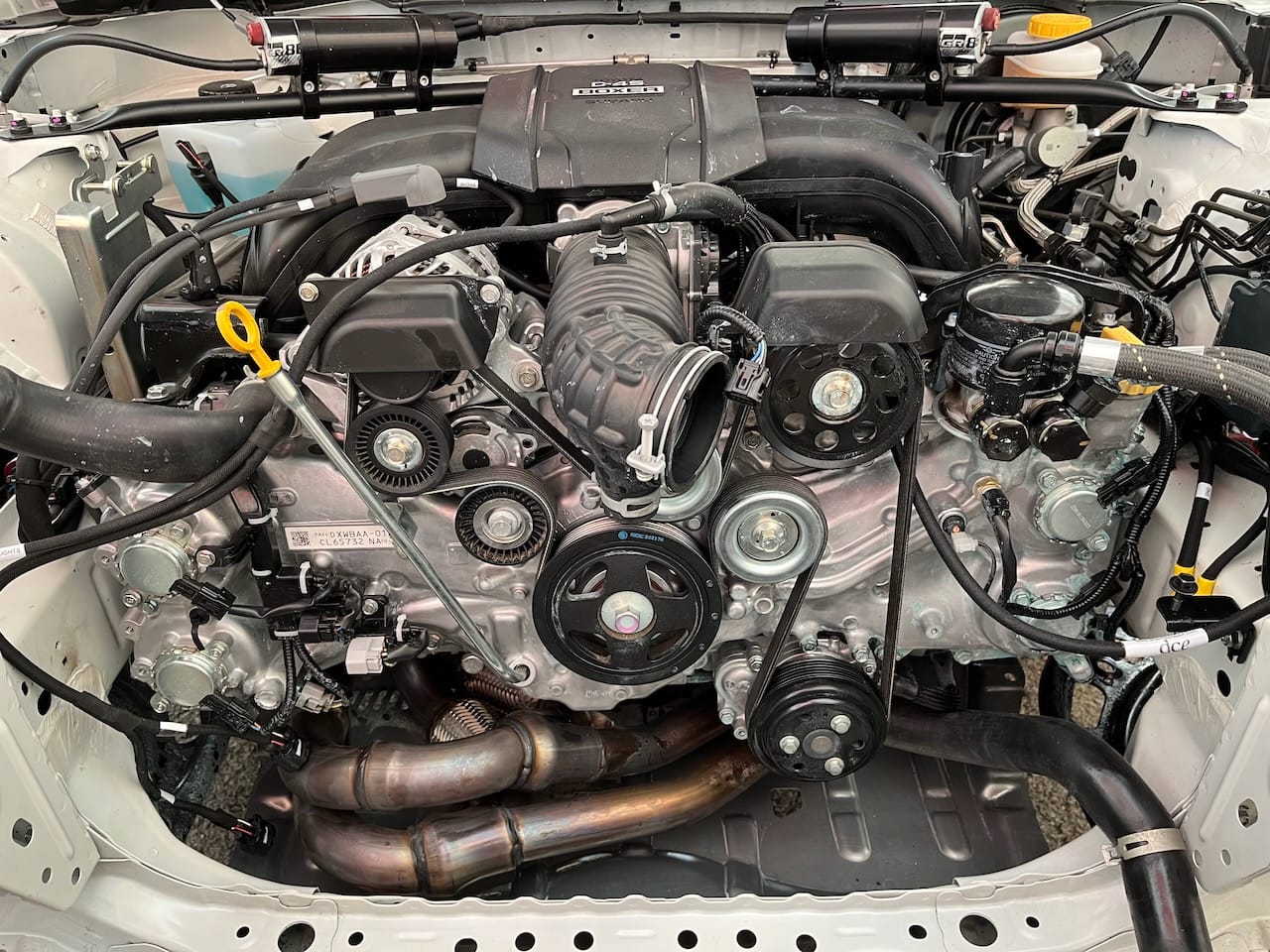

GR Cup cars have a few important modifications to the oiling system from stock, but overall the setup is very similar to what many track day enthusiasts run:

- Factory oil filter (SU003-08412)

- Deleted factory heat exchanger (directly below oil filter on stock car)

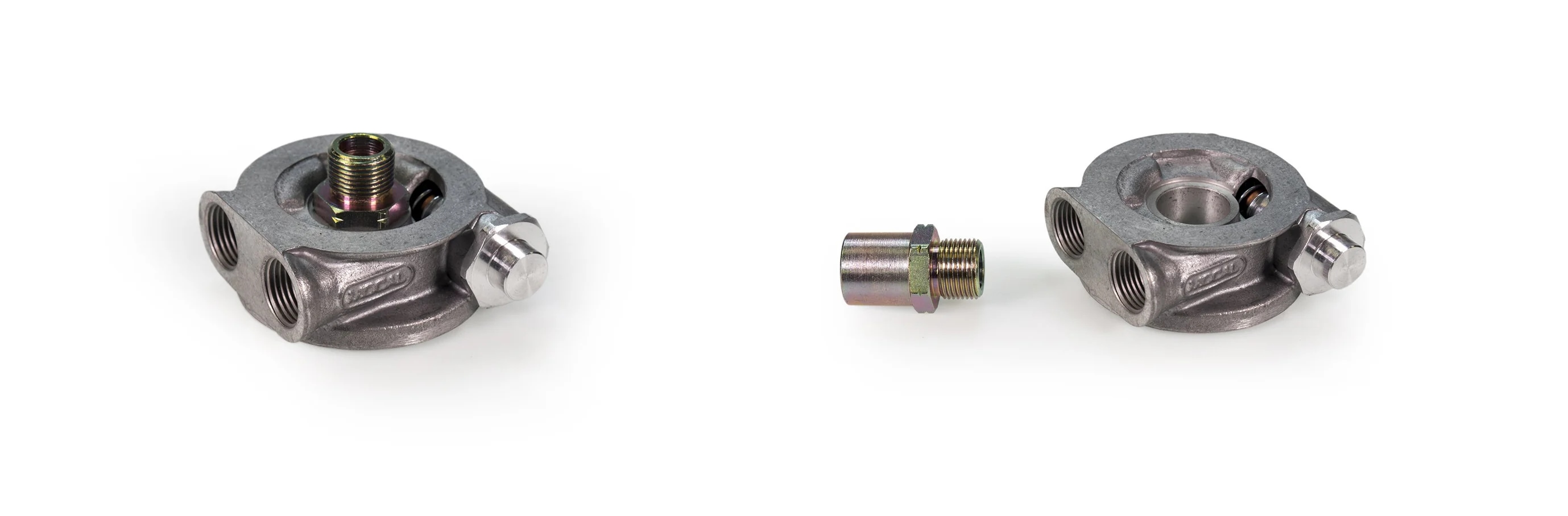

- Sandwich plate (Mocal)

- Banjo fittings attached to sandwich plate (appears to be from ColorFittings)

- Goodridge 910 AN-10 oil lines

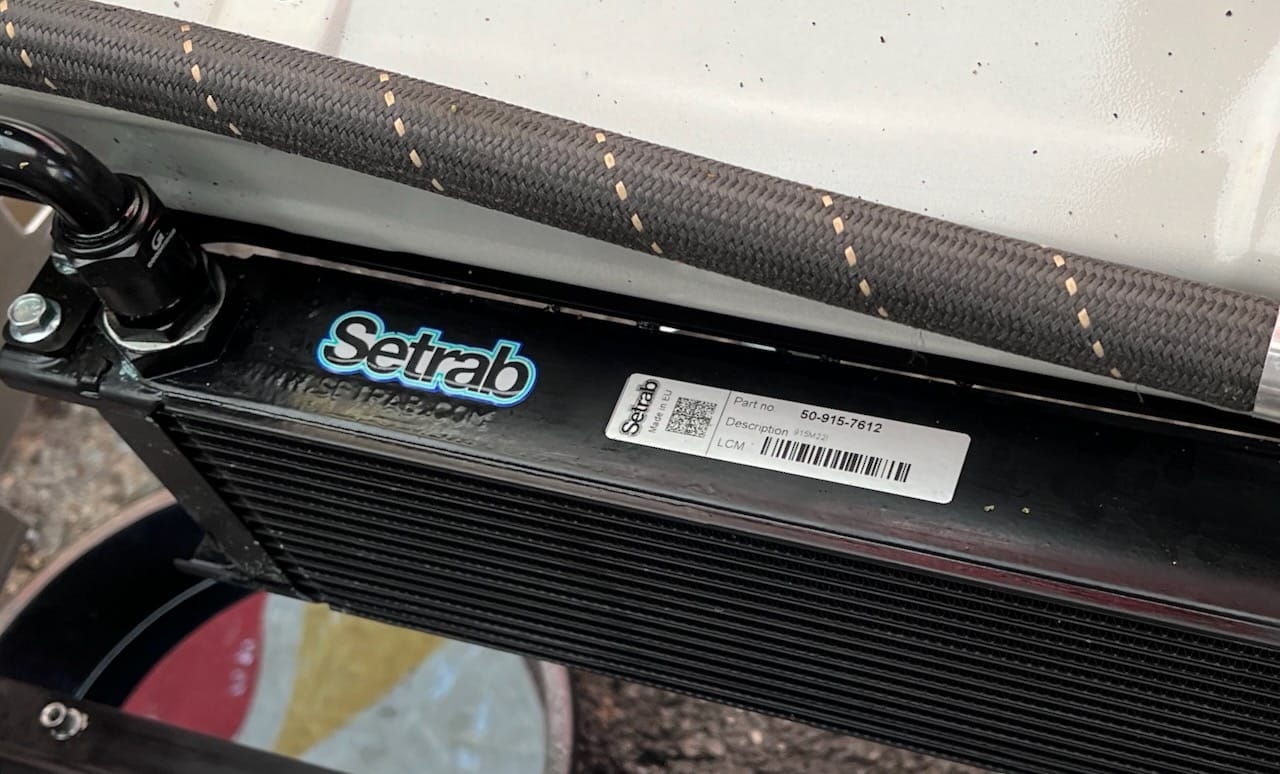

- Setrab oil cooler core (9-series 15 row, part number 50-915-7612)

- Oil pressure sensor at OEM oil pressure switch location (installed after COTA 2023)

- Unshielded custom headers (Borla)

The following pictures from at Sonoma Raceway on April 1, 2023 show this setup in detail:

Oil pan

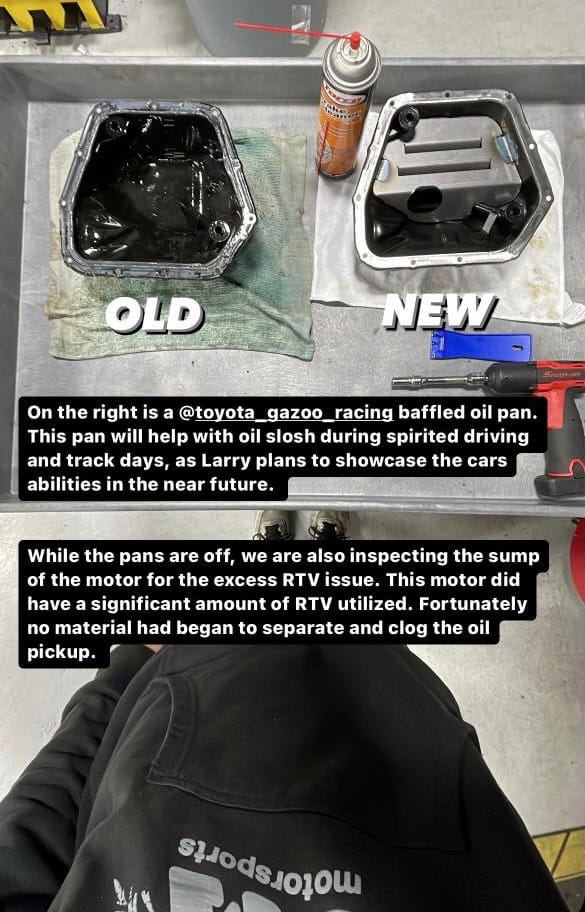

The GR Cup car has a modified OEM oil pan, with a welded-in baffle. It does not have any additional capacity. I was able to find a photo of the baffled pan courtesy of an Instagram story from Larry Chen, who was provided a GR Cup baffle by Toyota for his SEMA build.

During the first event of the 2024 season, at Sonoma, I confirmed that this design is still unchanged.

You can see that a louvered, horizontal plate has been bent downward toward the front of the engine to prevent surge forward on braking. The OEM oil return piping is retained.

Motor oil

GR Cup uses a spec motor oil, Mobil 1 FS 0W40. This full synthetic oil is branded as “European Car Formula” because it has certifications for use with various Porsche, VW, Mercedes, and BMW engines. It’s readibly available at very reasonable cost.

Fill level

Specified fill volume is 6.0 US quarts in the sump, with an additional 1.0 US quarts in the oil cooler circuit. So there is a total of 7.0 US quarts combined. The drain and fill procedure specifies leaving the oil in the oil cooler circuit, draining the sump, and refilling with 6.0 US quarts, which would equate to a 0.7 US quart overfill.

Temperature

The digital dash display used in the GR Cup car is a dedicated Bosch motorsports unit. It is programmed to warn the driver if oil temperatures are too high. The set points are:

| Temp (°C) | Temp (°F) | Warning level |

|---|---|---|

| 125 | 257 | Yellow |

| 130 | 266 | Red |

These levels are a good reference for amateurs, but keep in mind that this is Toyota's upper limit with 0W40. With lower viscosity oils, you will see lower pressures at these temperatures. For example, these temperatures with 0W20 may be unsafe for your engine.

Some teams have (illegally) tried using different oils to see if there is a performance improvement from running a different oil, like Motul 300V Power 0W-30. In theory, slightly lower viscosity might provide a power benefit. There was no measurable improvement.

Engine cooling

The GR Cup car appears to use the stock radiator, although I have not confirmed this. It has a custom shroud, which also supports the front splitter. The shroud also has an integrated grill, which sits behind the OEM plastic grill and protects the radiator and oil cooler from debris.

The set points for coolant temperature warnings are quite a bit lower than for oil temperature:

| Temp (°C) | Temp (°F) | Warning level |

|---|---|---|

| 100 | 212 | Yellow |

| 105 | 221 | Red |

The coolant specified is the same as stock, Toyota 50/50 Pre-Diluted Super Long Life Blue.

GR Cup cars also come with a 3D printed hood vent to evacuate hot air from the engine bay and reduce pressure under the hood. The aluminum hood is an OEM part (which is actually quite light) with the vent and aero latches added at the GR Garage.

Sealed engine

Other than the changes above, the engine is a stock FA24D, which is sealed by Toyota. This means teams are not allowed to make additional modifications to the engine internals.

Teams are allowed to rebuild engines with identical parts and a few teams did this between the 2023 and 2024 seasons.

Non-engine modifications

Transmission

The GR Cup car has a totally different transmission from the stock car, a dedicated motorsports sequential (i.e. dogbox) from SADEV (part number SCL82-17). The transmission has a dedicated oil cooler, pump, inline filter, and temperature sensor.

The spec oil is Mobil 1 Syn Gear Lube LS 75W-140.

Driveshaft

Likely a requirement to pair with the sequential transmission, the GR Cup car uses a custom driveshaft from DynoTech Engineering.

Differential

Somewhat surprisingly, the GR Cup car retains the OEM rear torsen differential.

In order to manage heat, it has a custom aluminum differential cover and an external oil cooler, pump, inline fiter, and a temperature sensor.

The spec oil used is Mobil 1 75W-140.

Drivetrain oil cooling

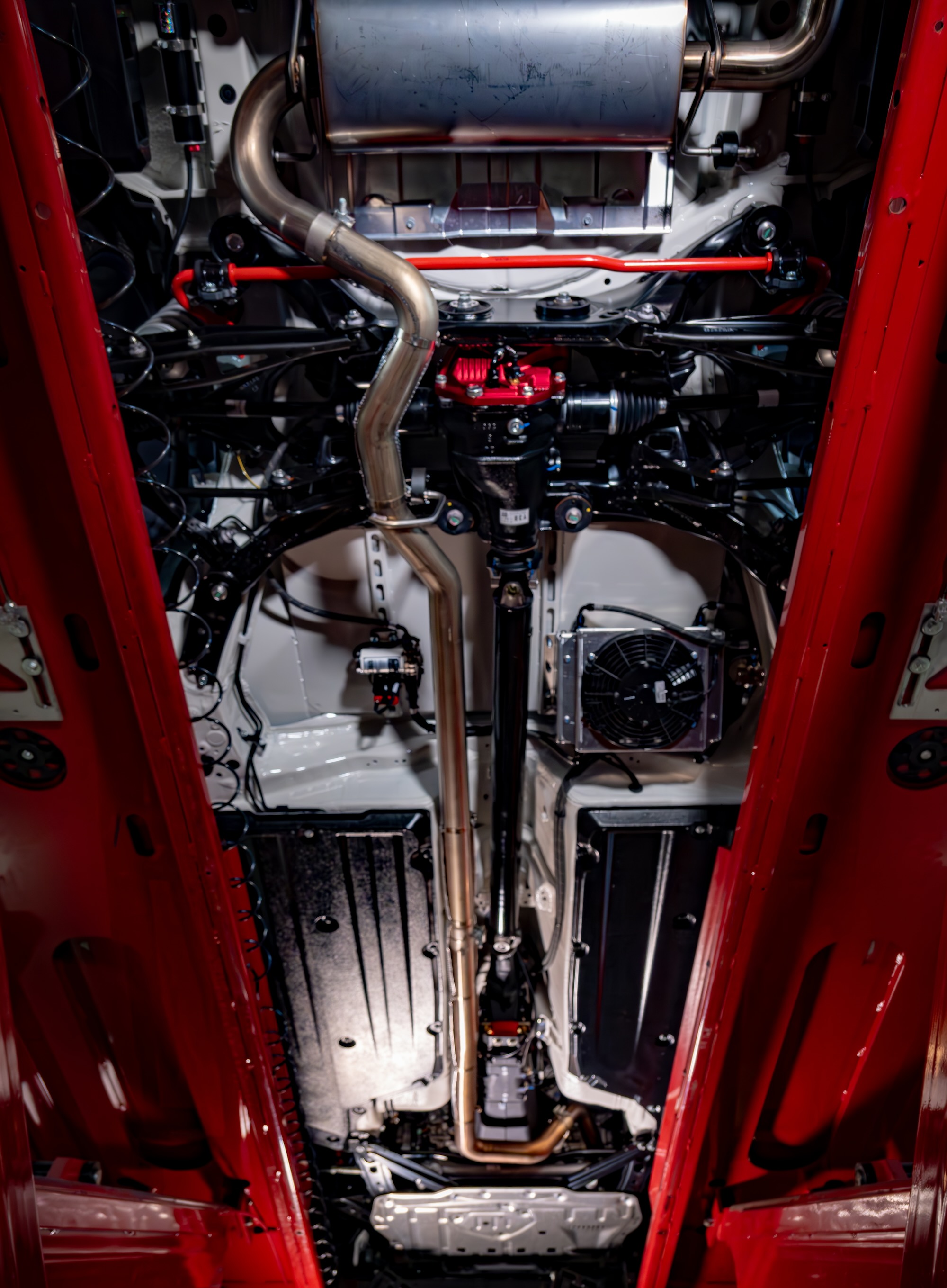

Thanks to an auction listing, we have underbody photos of the GR Cup car. By adopting a cabin-mounted fuel cell, the space under the car is freed up to be used for additional cooling.

Forward of the right-hand-side axle is a combined transmission and diff cooler, with a fan over two separate cooler cores that are mounted to a single bracket. Each cooler core has it's own pump and these are plumbed with Goodridge 910 hoses.

Growing pains

There have a been a couple of revisions to the GR Cup car to address issues since its introduction, as should be expected for any newly built race car platform.

Oil cooler crush washer

A team at Sebring 2023 had their oil filter come loose and they lost all oil. Luckily, this happened at turn 17, so the driver was able to immediately go into the pits and avoid catastrophic damage.

It was determined that the threaded adapter that fastens the sandwich plate to the block backed out. TGRNA mitigated this issue by introducing an optional copper crush washer that fits between the sandwhich plate and the threaded adapter.

Port injector issue

There was a port injector issue that was resolved bit fitting a new wiring harness. There were no issues with the injectors themselves.

Cam phase positioning errors

Another issue was camshafts becoming out of phase, which lead to a loss of about 40 hp. This was quickly fixed early on in the series with a new ECU flash provided from Bosch. There was also an alert added to the dash, so if the problem reoccurs, the driver will be notified and they can re-cycle the system.

Track record

How has the GR Cup car held up? According to my sources, there were 5 engine failures in 2023:

- COTA #1: Team forgot to add oil after oil change

- COTA #2: Team intentionally underfilled motor oil to achieve a performance advantage

- COTA #3: Second failure from intentionally underfilling motor oil

- Connecting rod broke, bearing did not appear to be the cause

- Overheated engine led to failure, suspected maintenance issue

So the 3 rumored failures at COTA did in fact happen, but they were caused by inappropriate actions by teams and do not necessarily indicate anything about FA24 reliability.

Since COTA 2023, a minimum oil fill level is strictly enforced by TGRNA and all cars have been modified with oil pressure sensors. Only Toyota and Bosch have access to the oil pressure data channels currently.

The other failures above don't appear to be particularly concerning, based on the information I have. Many teams are running the same engines without a rebuild for 2024, so we'll get more data on how these engines do this year.

That said, I do know that these cars are still experiencing severe oil pressure drops in certain corners, like T2 at Sonoma. I know that there were no failures at Sonoma in 2024, but I don't have any information on subsequent races.

Ultimately, we still don't know the exact relationship between the pressure drops and bearing failures, but I continue to believe we need more robust modifications to the oiling system (such as the high capacity oil pan I'm developing with Verus Engineering) to reduce or hopefully even eliminate the pressure drops for long term track usage.

If you have more information for me, feel free to reach out on Instagram @900brz or the email link in this site’s footer.