Oil Cooler, Rev. 2

After my engine failure this September while testing a prototype baffle, I planned to replace my oil cooler core and retain the rest of my Jackson Racing oil cooler setup.

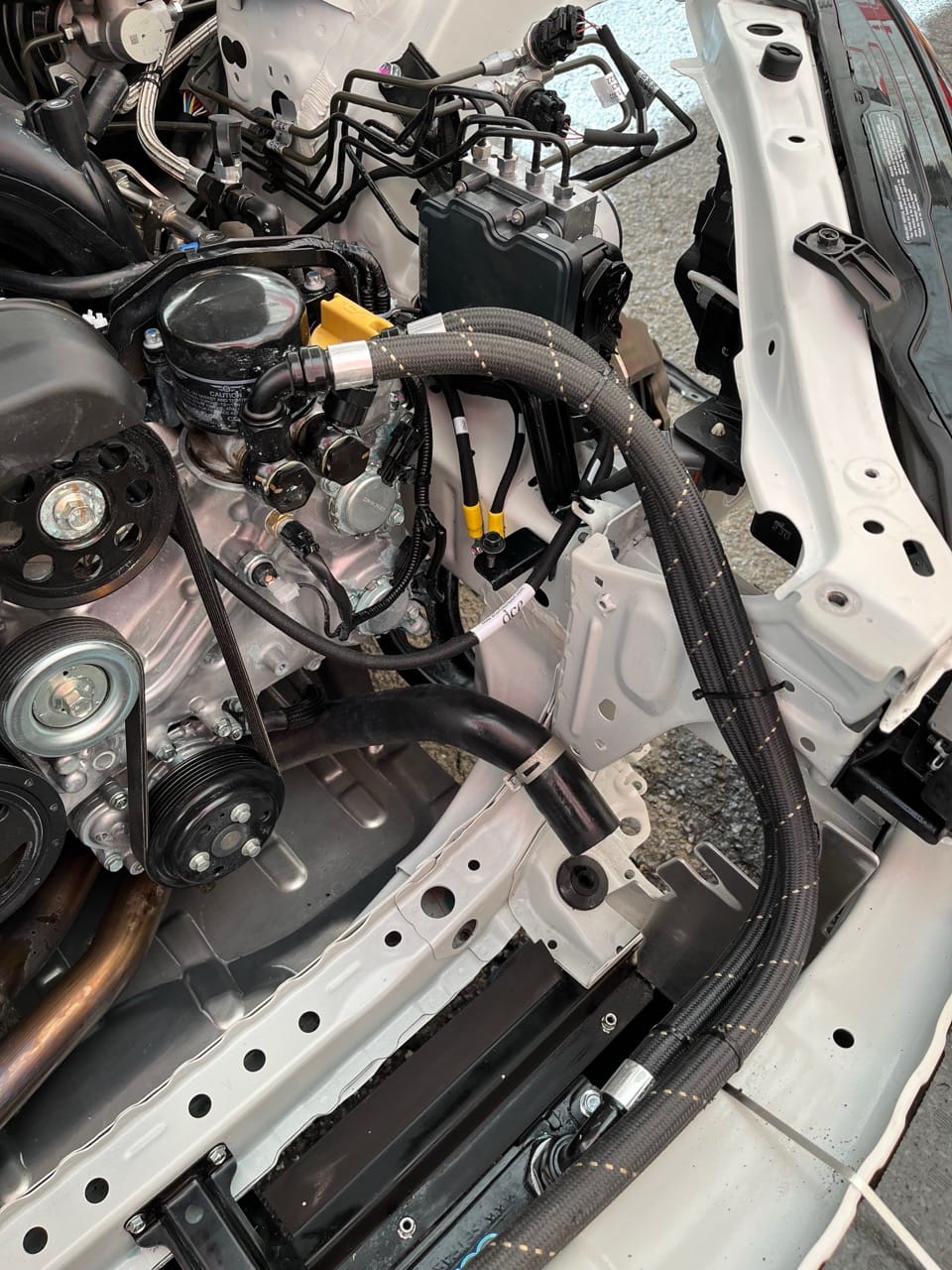

However, when attempting to reinstall the oil cooler, Ezekiel from CM AutoHaus, recognized that my oil cooler lines had been damaged by abrasion and could not safely be reused. If left unaddressed this would almost certainly result in a puncture. Leaks in pressurized oil lines can cause engine failures and, potentially even worse, fires.

I told him I’d figure it out later and to proceed with the rest of the engine swap.

This gave me an opportunity to rethink my oil cooler setup. I had seen a couple other members of 86 Challenge either make their own setups from individual components, or tweak existing kits. I decided to dig in and learn more.

Oil cooling principles

Compared to stock configurations, adding an oil cooler introduces a few tradeoffs that must be managed:

- Increased cooling is pure beneficial for track conditions, but can cause execcessive cooling on the street. This can lead to lower fuel economy and slower evaporation of any condensation in the oil.

- It appears to slightly increase the time it takes the engine to build pressure on startup, which could increase wear.

- The additional circuit length and diameter of the oil cooler lines can lead to increased flow resistence, decreasing pressure available at the crankshaft and main bearings.

Oil cooler core

Pegasus Auto Racing has a great resource detailing the tradeoffs when choosing an oil cooler core, Choosing and Using Engine Oil Coolers.

This section, in particiular, can help you develop intuition about how core size affects flow restriction:

- Oil coolers introduce a flow restriction. Our goal is to minimize this restriction.

- There is a direct relationship between plate length and restriction.

- Longer plates (rows) = more restriction.

- Shorter plates (rows) = less restriction.

- There is a direct relationship between plate length and cooling effect.

- Longer plates (rows) = more cooling.

- Shorter plates (rows) = less cooling.

- There is an inverse relationship between the number of plates and restriction.

- More plates (rows) = less restriction.

- Fewer plates (rows) = more restriction.

- There is a direct relationship between the number of plates and cooling effect.

- More plates (rows) = more cooling.

- Fewer plates (rows) = less cooling.

- Two coolers with similar cooling area will have similar cooling performance.

So, if you keep the width of your core the same and add height, you get both more cooling and less flow restriction.

Lines and fittings

When it comes to lines, the three most important factors that affect flow restriction are length, diameter, and bends:

- The longer the lines, the more restriction.

- The smaller the internal diameter, the more restriction.

- The sharper the bends and turns in the path, the more restriction.

The Jackson Racing kit that I have already does a pretty good job of minimizing restriction due to the path the oil takes. They use 45° AN fittings at the sandwich plate and at the cooler core. This is preferrable to banjo style fittings, which force the oil to take a sharper set of turns.

One area where other setups may have an advantage is the Jackson Racing kit retains the factory heat exchanger. We believe the factory heat exchanges costs the system about 3-5 psi of pressure. However, retaining the factory heat exchanger does mean the coolant can warm the oil in street operation, which helps mitigate one of the downsides of an oil cooler.

My new setup

I ended up reusing the Jackson Racing sandwich plate and oil cooler core mounting bracket. That also meant I would stay with the same core width. I increased the height of my cooler core from a 15 row Setrab core to a 20 row Setrab in order to increase cooling and reduce restriction.

I also switched to different AN lines to reduce restriction. After talking with @nostreetracing86 and @tor1059, I decided to go with Goodridge 910 hoses, ordered from Pegasus.

These hoses are mode from aramid (i.e. Kevlar) and PTFE (i.e. Teflon) for abrasion resistance. They also afford a larger internal diameter than traditional AN hoses. This has a superlinear affect on flow restriction, so even a small increase in internal diameter can has a large impact on flow restriction. I used Poiseuille’s law to calculate the improvement in flow restriction:

| Hose | Internal Diameter | Improvement in restriction |

|---|---|---|

| Aeroquip StartLite Aramid Braided Hose | 0.56" | Baseline |

| 910 PTFE Lined Aramid Braided Hose | 0.63" | 38% |

In an email exchange, @nostreetracing86 received the folwing information from Pegasus comparing 910 with StartLite hose:

The PTFE liner is more resistant to stretching than rubber, which is how the 910 hose can use a thinner wall and still maintain a higher operating pressure rating than Startlite. (Note that the pressure ratings for both types is well in excess of the pressures that a Setrab cooler can take, and much higher than any oil system should ever see.) Both types are on the NHRA list of approved oil hoses.

We have not seen or heard of any failures of either type of hose which were not directly caused by gross errors in assembly - using the wrong type of hose ends, using the wrong size hose ends, or simply not even bothering to look at the instructions.

Startlite (and its sister, standard stainless braided hose) was conceived in part to be reliably assembled by non-mechanics with minimal training. 910 hose was engineered specifically for IndyCar fuel systems but the Goodridge engineers recognized its potential for oil systems as well.

I looked back at some of my photos during this research and found that the same Goodridge 910 hoses are used on GR Cup cars.

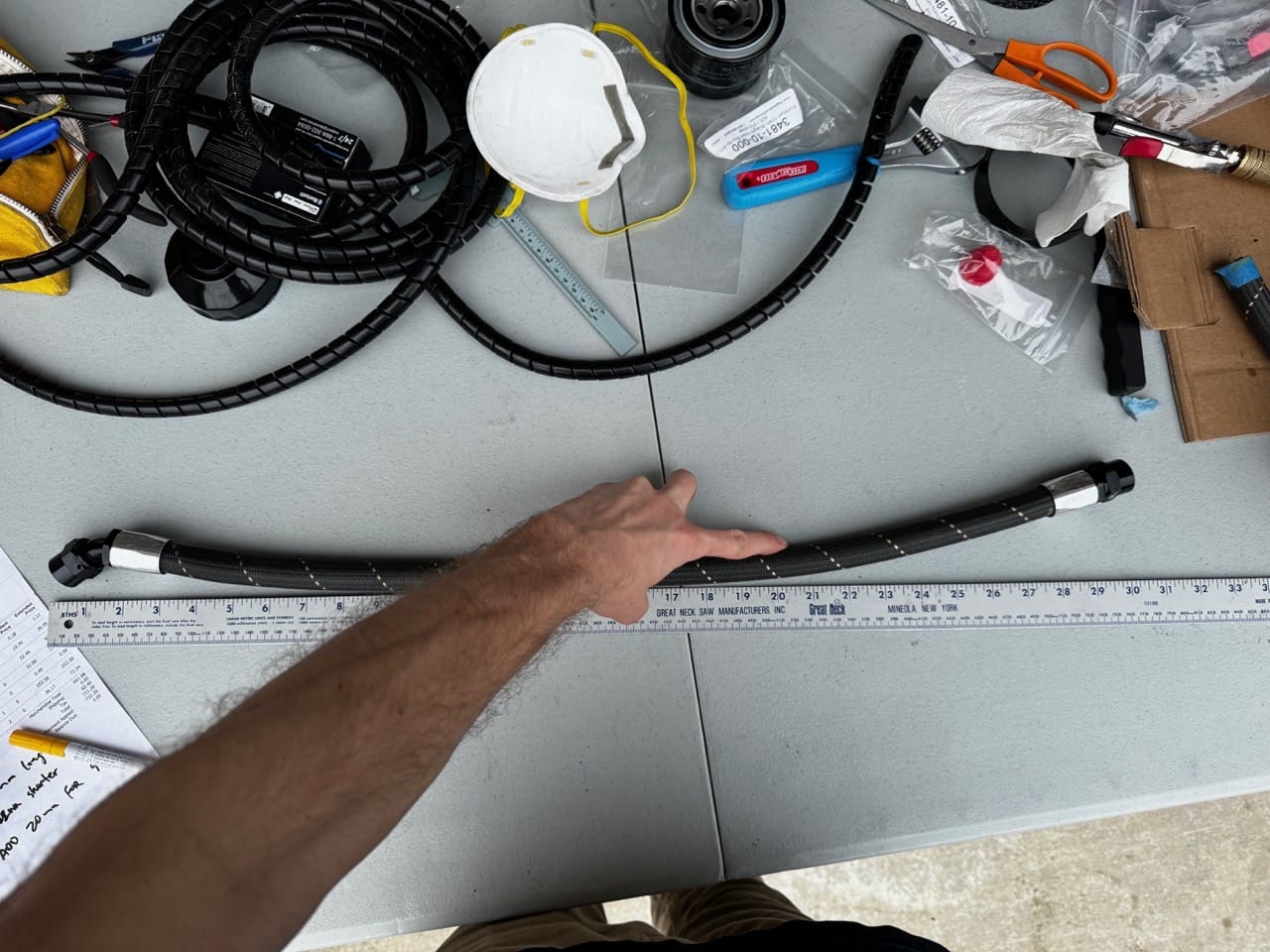

You need to cut these to length and install the hose fittings yourself. I used a bench vise and angle grinder to cut the hose. It's important to do this correctly, so I purchased some cheap AN10 hoses on Amazon to do a test run. This also allowed me to dial in the exact hose lengths I wanted and make a single cut with the expensive hose.

I spent hours cutting, installing fittings, and installing the cheap Amazon hoses before I was happy with the lengths and ready to move on to the production hoses. Taking the time to dial in the hose lengths to avoid rubbing is recommended regardless of which hoses you get.

It’s also a good idea to use zip ties to hold the hoses in place. You can fish them through some of the holes in the crash structure to prevent everything from moving, but make sure not to crush the lines with the force from the zip ties.

I finished off the build with spiral wrap around the hoses for additional abrasion protection.

I will be report back on the performance of this setup. For now, my numbers aren’t directly comparable to my previous setup because ambient temps are so much lower here in California compared to the summer.

Appendix 1: Line lengths

I’m hesitant to share exact line lengths because there are differences in the setup that can affect how long your lines need to be.

For example, the Jackson Racing kit uses 45° AN to M22 fittings at the core side and bolts directly onto the core. I used a 45° M22 to AN10 adapter fitting attached to the Setrab core and then connected a straight AN10 fitting to it. Even if I wanted to end up with the same line length as the JR kit, I would need to cut my hose shorter to compensate for the additional length of the straight fitting.

CAUTION: Please use these numbers as a starting point and dial in your own setup. Do not cut your hoses to these measurements without doing your own test fitting!

| Run | Hose length (in.) | Length with fittings (in.) |

|---|---|---|

| Short | 28 ¾ | 30 ½ |

| Long | 45 ¾ | 47 ½ |

Appendix 2: Pegasus order

In case you are interested in doing a similar setup, here is the exact order I placed on Nov 6, 2023. I had about 1 ft of extra 910 hose after the install.

| Part No. | Description | Qty | Price | Row Price |

|---|---|---|---|---|

| 3296-10 | 10AN Threaded Plastic Plug, 7/8-14 Thread | 4 | 0.28 | 1.12 |

| 3481-10-000 | Aluminum 10AN Straight Hose End for 811 / 825 / 910 Hose | 2 | 19.79 | 39.58 |

| 3481-10-045 | Aluminum 10AN Hose End for 811 / 825 / 910 Hose, 45 Degree | 2 | 32.49 | 64.98 |

| 3490-10-FOOT | 910 Aramid Braided PTFE Racing Hose, 10AN - per foot | 7 | 32.90 | 230.30 |

| SET-20-568019-V10 | Setrab 019 Viton O-Ring for M22 Ports | 2 | 0.49 | 0.98 |

| SET-920-7612 | Setrab Series 9 Oil Cooler, 20 Row, M22 Ports | 1 | 252.58 | 252.58 |

| SET-M22AN10-45 | Setrab M22 to 10AN Male Adapter | 2 | 36.17 | 72.34 |

| Item Total | 661.88 | |||

| Tax | 60.40 | |||

| Total (USD) | 722.28 |

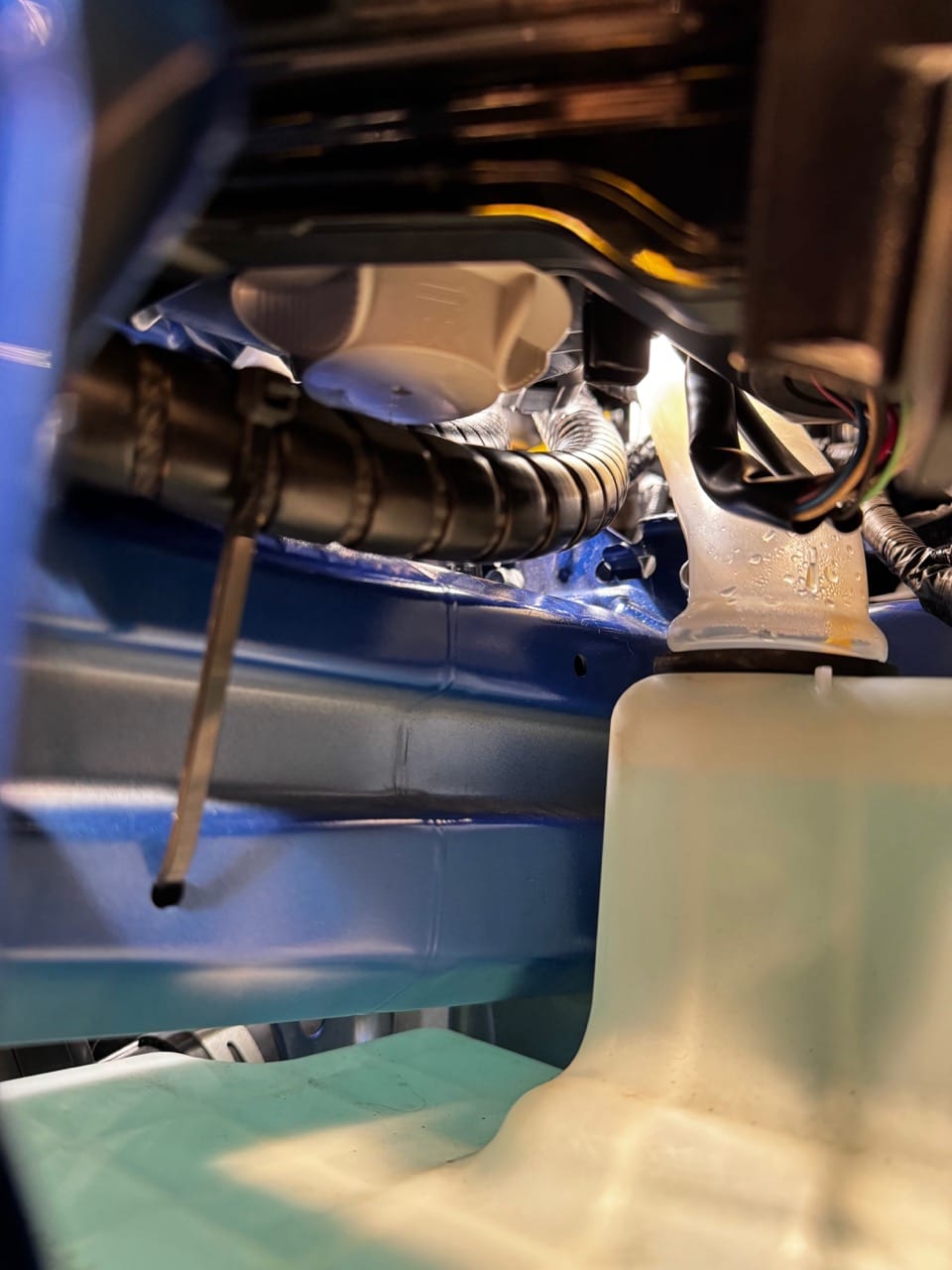

Appendix 3: Abrasion on other Jackson Racing oil cooler installs

Some friends have also found issues with rubbing on their Jackson Racing oil cooler installs. Here is an example from a Gen 1 BRZ installed professionally at a Bay Area shop. It is important to install carefully and check for rubbing periodically.